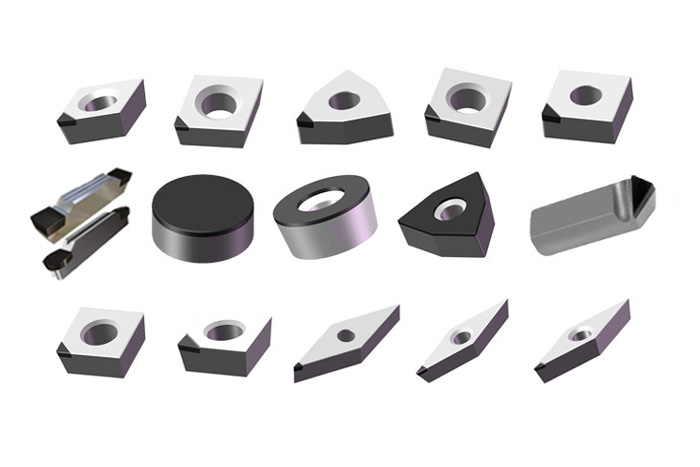

In the world of machining, precision and efficiency are paramount. To achieve optimal results, manufacturers and engineers are constantly seeking innovative tools and technologies. One such tool that has gained significant attention is the Polycrystalline Diamond (PCD) insert.

PCD inserts are cutting tools that are widely used in various machining operations, including turning, milling, and drilling. What sets them apart from conventional inserts is the use of synthetic diamond particles, which are bonded together using a high-pressure, high-temperature process. This unique composition gives PCD inserts exceptional hardness, wear resistance, and thermal conductivity, making them ideal for machining applications that involve high-speed and high-temperature conditions.

One of the key advantages of PCD inserts is their extended tool life. The hardness of the diamond particles ensures that the inserts can withstand the most demanding machining operations without losing their cutting edge. This longevity translates into reduced tool changeovers, increased productivity, and cost savings for manufacturers. Additionally, the wear resistance of PCD inserts minimizes the need for frequent regrinding, further enhancing their efficiency.

Another notable benefit of PCD inserts is their ability to achieve superior surface finishes. The sharp cutting edges and low friction coefficient of the diamond particles result in smooth and precise cuts, reducing the need for secondary finishing operations. This not only saves time but also improves the overall quality of the machined components.

PCD inserts find applications in a wide range of industries, including aerospace, automotive, and medical. In the aerospace sector, where high-performance materials like titanium and composites are commonly used, PCD inserts excel in providing clean and accurate cuts. Similarly, in the automotive industry, PCD inserts are highly effective in machining aluminum alloys and hardened steels, ensuring precise component manufacturing.

Furthermore, PCD inserts are environmentally friendly. Their long tool life and reduced need for regrinding contribute to lower energy consumption and waste generation. This aligns with the growing emphasis on sustainability and resource efficiency in modern manufacturing practices.

It is worth noting that while PCD inserts offer numerous advantages, they also come with certain considerations. Due to their high initial cost, they may not be suitable for all machining applications. Additionally, PCD inserts require careful handling and proper setup to prevent damage to the delicate diamond cutting edges.

PCD inserts have revolutionized the machining industry with their exceptional hardness, wear resistance, and thermal conductivity. Their extended tool life, superior surface finishes, and versatility make them a valuable asset for manufacturers seeking to enhance performance and efficiency. With long production history and rich production experience, our pcd inserts are sold well all over the world. Welcome to contact us for free inquiry at any time!