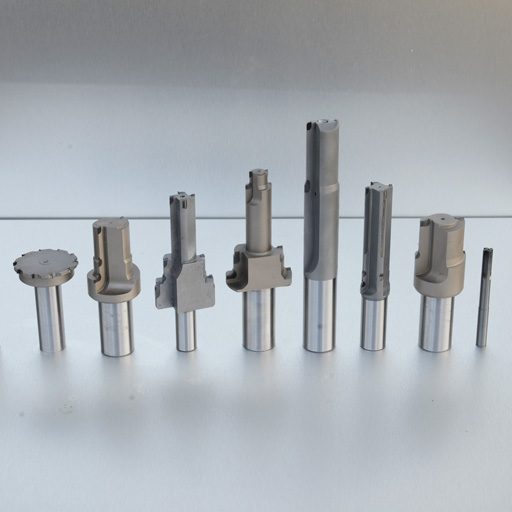

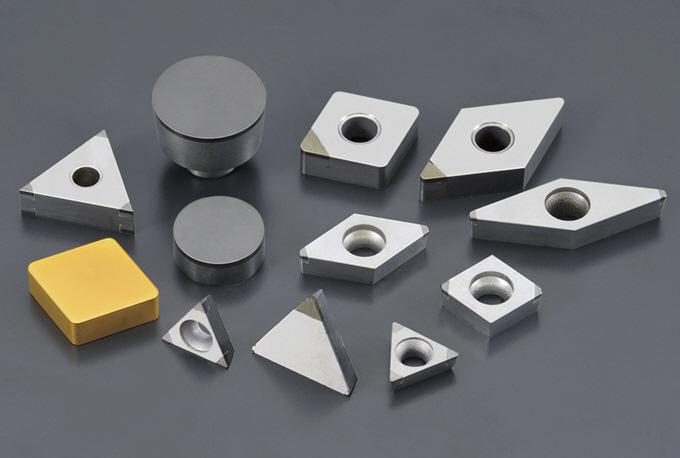

PCD diamond compact is cut, welded, and sharpened into a PCD inserts. PCD cutting tools are widely used in high-speed processing of other non-ferrous and non-metallic materials, and are widely used in automotive, aerospace, electronics and wood processing fields.

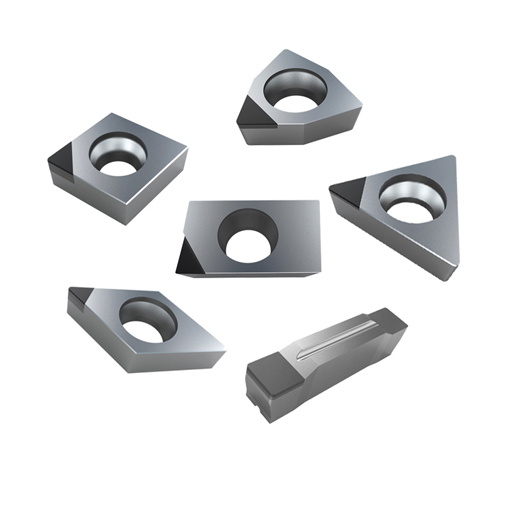

PCD inserts are divided into standard PCD inserts, PCD milling inserts, chipbreaker PCD inserts, and non-standard PCD inserts according to the form. PCD inserts have front angle, back angle, flat angle, chip breaker, etc. Our main products include pdc diamond compact, pdc drill bit, diamond wire, diamond saw blade, diamond grinding wheel etc. Welcome to contact us interested for free quotation. We will replay as soon as possible.