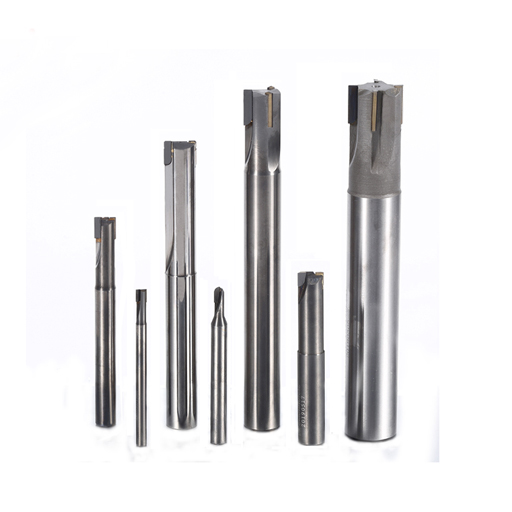

PCD endmills are used to process workpieces of various materials, such as non-ferrous metals: aluminum, aluminum alloy, aluminum cast alloy, copper, copper alloy, zinc, zinc alloy and other materials; non-metallic materials: graphite, carbon fiber composite materials, glass fiber, new composite materials and other materials processing. PCD endmill for sale can be used to machine cast aluminum alloy engine casings.

Features of PCD endmill

1. The PCD endmill has high machining accuracy, high machining efficiency, high hardness, high wear resistance, high thermal conductivity, and strong toughness, which is superior to ordinary carbide milling cutters.

2. High-speed cutting and hard material cutting can be realized.

3. The surface quality of the PCD milling cutter can reach the mirror effect, and the roughness is the original general tungsten steel milling cutter.

4. Our PCD milling tools have a long service life. Its service life is 10 to 20 times that of carbide milling cutters.