| Product Introduction | |||||||||

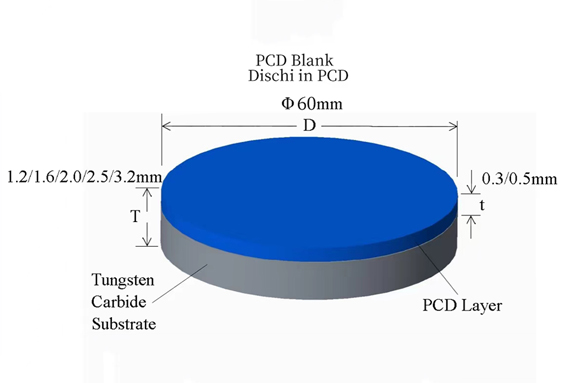

| PCD |

Coarse Grain Diamond | Medium Grain Diamond | Fine Grain Diamond | ||||||

| Type | HHPD032-A | HHPD032-B | HHPD025-A | HHPD025-B | HHPD012-A | HHPD010-A | HHPD010-B | HHPD010-C | HHPD005-A |

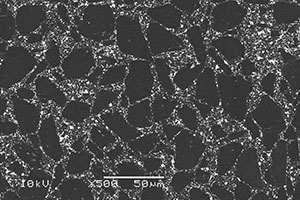

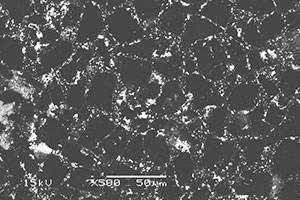

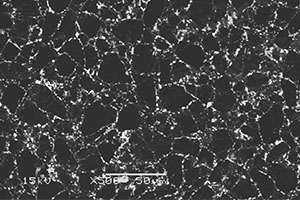

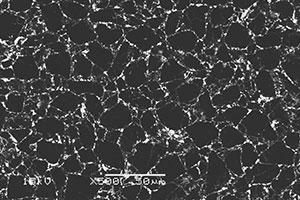

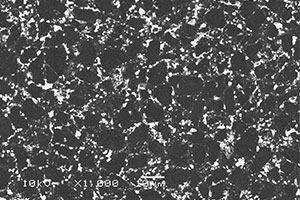

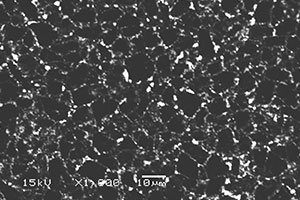

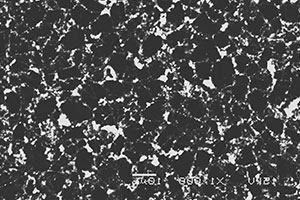

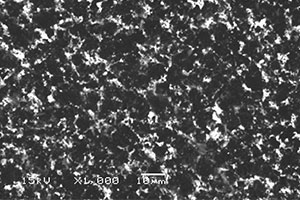

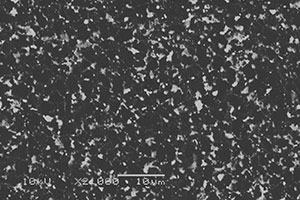

| Structure Image By Electron Microscope |

|

|

|

|

|

|

|

|

|

| Diameter (mm) |

48.0 |

||||||||

| Total Thickness (mm) |

1.0/1.2/1.6/2.0/2.5/3.2 | ||||||||

| PCD Layer Thickness (mm) |

0.5±0.15 | ||||||||

| Average Grain Size (μm) |

30+2 | 30+2 | 25 | 25 | 10+2 | 10 | 10 | 10 | 5 |

| Characters | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is strengthened by the order of 010-A,012-A,010-B and 010-C, EDM cutting performance is strengthened by the order of 010-A,012-A,010-C and 010-B. | High impact toughness, suitable for EDM cutting, extremely high degree of surface finish. | ||||||

| Application | Used in highly abrasive materials, such as ceramic, hard metal, silicon carbide, stone and laminate flooring. | Specially used in chipboard and other places where require rough feed. | Used in laminate flooring, density board, carbon fiber materials, silicon carbide, high-silica aluminum alloy. | Used in the manufacturing of common wood saw blade and products requiring EDM. cutting. | Used in fine processing of circuit boards, silicon-aluminum alloy and copper alloy. | Used in processing of wood, circuit boards, low silicon-aluminum alloy and fine ceramics. | Used in manufacturing all kinds of segments with EDM cutting. | Used in the places with fine processing where require rough feed and low abrasive resistance. | Used in the places where require high degree surface finish, such as low silicon-aluminum alloy, non-ferrous metal, semiconductor and plastic. |